Industry 4.0 & Smart Manufacturing: The Future of Mechanical Engineering

The world of manufacturing is undergoing a revolutionary transformation with the advent of Industry 4.0 - the era of smart, connected, and data-driven production systems. For mechanical engineers, this evolution opens a dynamic future where traditional methods are integrated with digital technologies to achieve greater efficiency, sustainability, and innovation.

At Presidency University, the Presidency School of Engineering, particularly the Department of Mechanical Engineering, is equipping future engineers with the knowledge and skills to thrive in this new industrial era.

What is Industry 4.0?

Industry 4.0, often called the Fourth Industrial Revolution, is characterized by the integration of Cyber-Physical Systems (CPS), Internet of Things (IoT), Artificial Intelligence (AI), robotics, big data analytics, and cloud computing into manufacturing processes. Unlike traditional manufacturing, where machines operate in isolation, smart factories create an interconnected ecosystem where devices communicate, learn, and adapt in real time.

Smart Manufacturing: A Game-Changer

Smart manufacturing represents the practical application of Industry 4.0 principles. By leveraging automation, sensors, and data analytics, industries can achieve:

- Predictive Maintenance: Machines can anticipate breakdowns before they happen, reducing downtime.

- Customization at Scale: Products can be tailored to customer needs without sacrificing speed.

- Energy Efficiency: Smart systems optimize power usage, promoting sustainable practices.

- Quality Control: Real-time monitoring ensures precision and consistency.

This shift transforms the role of mechanical engineers from pure design and production to being innovators who bridge mechanical systems and digital intelligence.

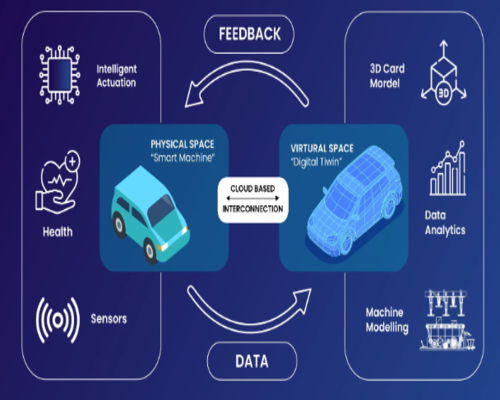

The Role of Mechanical Engineers in Industry 4.0

Mechanical engineers remain central to this revolution. With expertise in materials, design, thermodynamics, and manufacturing processes, they now also need to adapt to digital simulation, data-driven decision-making, and robotics integration. Some emerging opportunities include:

- Designing digital twins for real-time simulation.

- Developing automated manufacturing systems with AI integration.

- Implementing sustainable practices through smart energy systems.

- Applying 3D printing and additive manufacturing for rapid prototyping.

At the Department of Mechanical Engineering, Presidency University, students are trained to be versatile professionals who can blend classical engineering fundamentals with modern digital competencies.

Presidency University’s Vision for the Future

Presidency School of Engineering emphasizes experiential learning, industry collaborations, and research in smart manufacturing. Through modern laboratories, project-based learning, and workshops, the Department of Mechanical Engineering ensures that graduates are well-prepared to lead in an Industry 4.0-driven future.

By nurturing innovation, creativity, and technical expertise, Presidency University is shaping mechanical engineers who will not only adapt to Industry 4.0 but also drive its advancements.

Conclusion

The fusion of mechanical engineering with digital technologies marks a new horizon in industrial growth. As Industry 4.0 and smart manufacturing reshape the global landscape, Presidency University’s Presidency School of Engineering stands at the forefront of preparing students to embrace this future. With the Department of Mechanical Engineering leading the way, graduates are poised to become innovators and leaders in the age of intelligent manufacturing.

Written by,

Dr. Prabhukumar Sellamuthu

Associate Professor, Dept of Mechanical Engineering

Rajanukunte, Yelahanka, Bengaluru, Karnataka, Pin: 560119, India

Rajanukunte, Yelahanka, Bengaluru, Karnataka, Pin: 560119, India

+91 9022092222

+91 9022092222