3D Printing & Additive Manufacturing: Redefining Prototype & Production

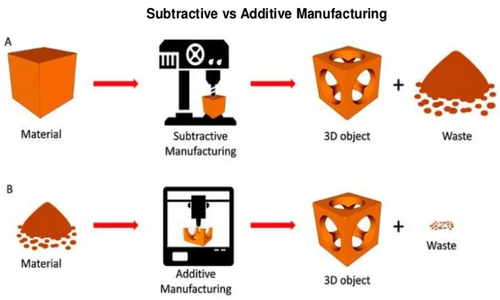

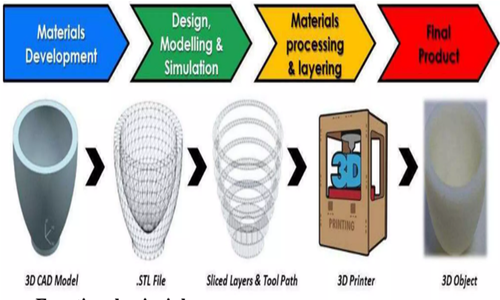

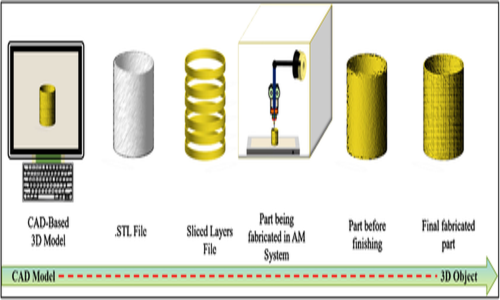

3D Printing, also known as Additive Manufacturing (AM), is a process of creating three-dimensional objects by adding material layer by layer, based on a digital 3D model. Unlike traditional manufacturing, which often involves subtracting material (cutting, drilling, milling), additive manufacturing builds the object from the ground up.

At Presidency University, the Presidency School of Engineering, particularly the Department of Mechanical Engineering, is equipping future engineers with the knowledge and skills to thrive in this new Technology.

What is 3D Printing?

3D printing refers to transforming three-dimensional models into physical objects that you can hold and touch. It is also called additive manufacturing, because the 3D model is created by “adding” layers upon layers of material until the object is fully formed. Fused Filament Fabrication (FFF) is the most common method of 3D printing.

Advantages

- Complex Geometries: Can create shapes that are impossible or very expensive with traditional methods.

- Customization: Easy to produce customized, one-off parts.

- Reduced Waste: Only uses the material needed for the part.

- Rapid Prototyping: Quick iteration cycles for product development.

- Tool-less Manufacturing: No need for mold or tooling.

Applications

- Aerospace: Lightweight, complex parts with optimized strength.

- Medical: Customized implants, prosthetics, surgical tools.

- Automotive: Prototyping and low-volume production.

- Consumer Goods: Custom jewelry, footwear, eyewear.

- Construction: 3D printing of building components and even whole structures.

- Education & Research: For prototyping and experimental manufacturing.

Challenges

- Material Limitations: Not all materials can be 3D printed.

- Speed: Often slower than traditional mass manufacturing.

- Cost: High-quality printers and materials can be expensive.

- Post-Processing: May require finishing (removing supports, polishing).

- Size Limitations: Printer build volumes limit the size of parts.

Future Trends

- Multi-material printing: Combining different materials in one print.

- Bio printing: Printing tissues and organs.

- Large-scale printing: Construction and automotive industries pushing bigger prints.

- Sustainability: Using recycled or biodegradable materials.

- AI & Automation: Smarter printers and improved design algorithms.

3D Printing: A Game-Changer

3D Printing (Additive Manufacturing) is revolutionizing traditional manufacturing by fundamentally changing how products are designed, developed, and produced. It shifts the paradigm from mass production to mass customization, and from slow, costly prototyping to rapid, cost-effective innovation.

D Printing is a game-changer because it transforms how we think about making things — breaking barriers of design, speed, cost, and customization. It empowers industries to innovate faster, reduce waste, and meet unique customer needs, driving the future of manufacturing and product development

The Role of Mechanical Engineers in 3D Printing

Mechanical engineers play a crucial role in advancing 3D printing technology and applying it effectively across industries. Their expertise bridges design, materials, manufacturing processes, and system integration, making 3D printing more efficient, reliable, and innovative

Examples of Mechanical Engineers’ Impact in 3D Printing:

- Designing lightweight aerospace brackets that reduce fuel consumption.

- Developing patient-specific orthopedic implants with improved fit and strength.

- Creating rapid prototypes for automotive components to accelerate development cycles.

- Optimizing print parameters to enhance durability of industrial tooling.

Mechanical engineers are at the heart of 3D printing innovation. They ensure designs are functional and manufactural, select the right materials, optimize processes, and validate parts for real-world use. Their work transforms 3D printing from a novel technology into a reliable, scalable manufacturing solution across many industries.

Presidency University’s Vision for the Future

Presidency School of Engineering emphasizes experiential learning, industry collaborations, and research in smart manufacturing. Through modern laboratories, project-based learning, and workshops, the Department of Mechanical Engineering ensures that graduates are well-prepared to lead in a 3D Printing Technology driven future. By nurturing innovation, creativity, and technical expertise, Presidency University is shaping mechanical engineers who will not only adapt to 3D Printing Technology but also drive its advancements.

Conclusions

3D printing and additive manufacturing have revolutionized the landscape of prototyping and production by offering unparalleled flexibility, speed, and cost-efficiency. These technologies enable rapid iteration in product development, reduce material waste, and allow for complex geometries that traditional manufacturing methods cannot easily achieve. As they continue to advance, 3D printing and additive manufacturing are not only reshaping how prototypes are created but are also increasingly becoming viable options for end-use production, driving innovation across industries from aerospace to healthcare. Ultimately, they are redefining manufacturing paradigms, fostering customization, and accelerating time-to-market in ways previously unimaginable.

Written by,

Dr. Ramachandra C.G.

Professor, Dept.of Mechanical Engineering

Rajanukunte, Yelahanka, Bengaluru, Karnataka, Pin: 560119, India

Rajanukunte, Yelahanka, Bengaluru, Karnataka, Pin: 560119, India

+91 9022092222

+91 9022092222